Check out our new company video:

![Compressor[1]](http://turbinate.com/wp-content/uploads/2015/09/Compressor1-1024x752.jpg) Drying service including dew point measurement

Drying service including dew point measurement

After pigging or other activities, water or another fluid might be present in the furnace tubes, process- and transferlines.

It is often not desirable to have these fluids present in these tubes when the process is started. We therefore have decided to extend our services with a drying service. We will use a large compressor, foam pigs and an air dryer to get rid of the fluids that might still be inside the tubes. To verify the result of this drying step we are also able to provide a dew point measurement. With our equipment we are able to reach a dew point of -40°C on most types of installations. If you would like to know more about our drying service do not hesitate to contact us.

Filter unit![Filter-unit-1024x664[1]](http://turbinate.com/wp-content/uploads/2015/09/Filter-unit-1024x6641-1024x664.jpg)

We believe it is important to reduce the amount of (soda)water that is being used, during the pigging process and during other water consuming processes. For that reason we have developed a large independent filter unitWith this filter we are able to reuse our pigging water instead of dumping the dirty water in the sewer. This obviously has a lot of benefits for our customers. We do not only require a lot less water, the impact of our activities on the effluent plant can be reduced to the absolute minimum as well. Of course this filter can also be used for other activities than pigging. If you would like to know more about our filter unit please do not hesitate to contact us.

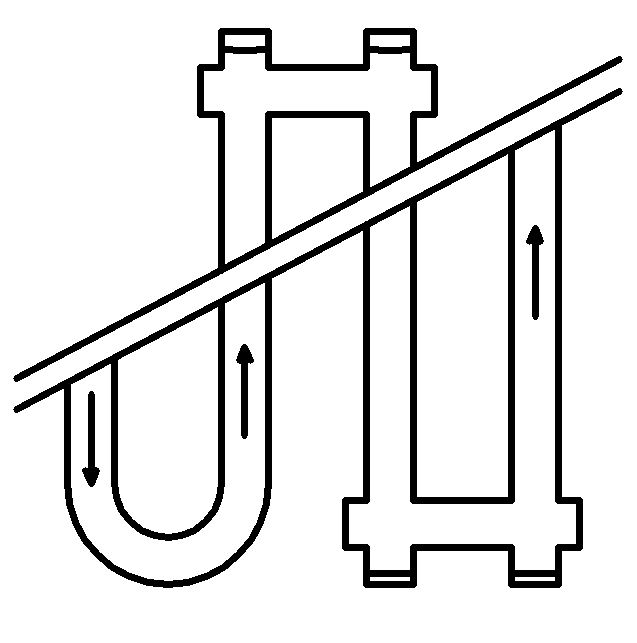

Plugged Bend Program

After solving the common header problem with our common header tool, the current biggest challenge in the pigging business is the plugged bends. Though most plugged bends can be passed with a mechanical pig, navigating the intelligent pig through a bend like this has proven to be a lot harder. Since the design of almost every plugged bend is different, it is hard to find one general solution that can be used at different refineries. Therefore we have started a customer specific plugged bend program.

After solving the common header problem with our common header tool, the current biggest challenge in the pigging business is the plugged bends. Though most plugged bends can be passed with a mechanical pig, navigating the intelligent pig through a bend like this has proven to be a lot harder. Since the design of almost every plugged bend is different, it is hard to find one general solution that can be used at different refineries. Therefore we have started a customer specific plugged bend program.

With this program we use one of the customers plugged bends to find the right configuration to pig and intelligent pig a furnace that is equipped with these plugged bends. Recently we successfully navigated a cleaning and intelligent ultrasonic pig through a plugged bend with the use of one of our own, patented, inventions. We believe that from now on we will be able to pig and inspect almost all of the furnaces with plugged bends that we previously could not pig or inspect.

If you are interested in participating in this program or if you would like more information please contact us.